Tunnel Data Management System

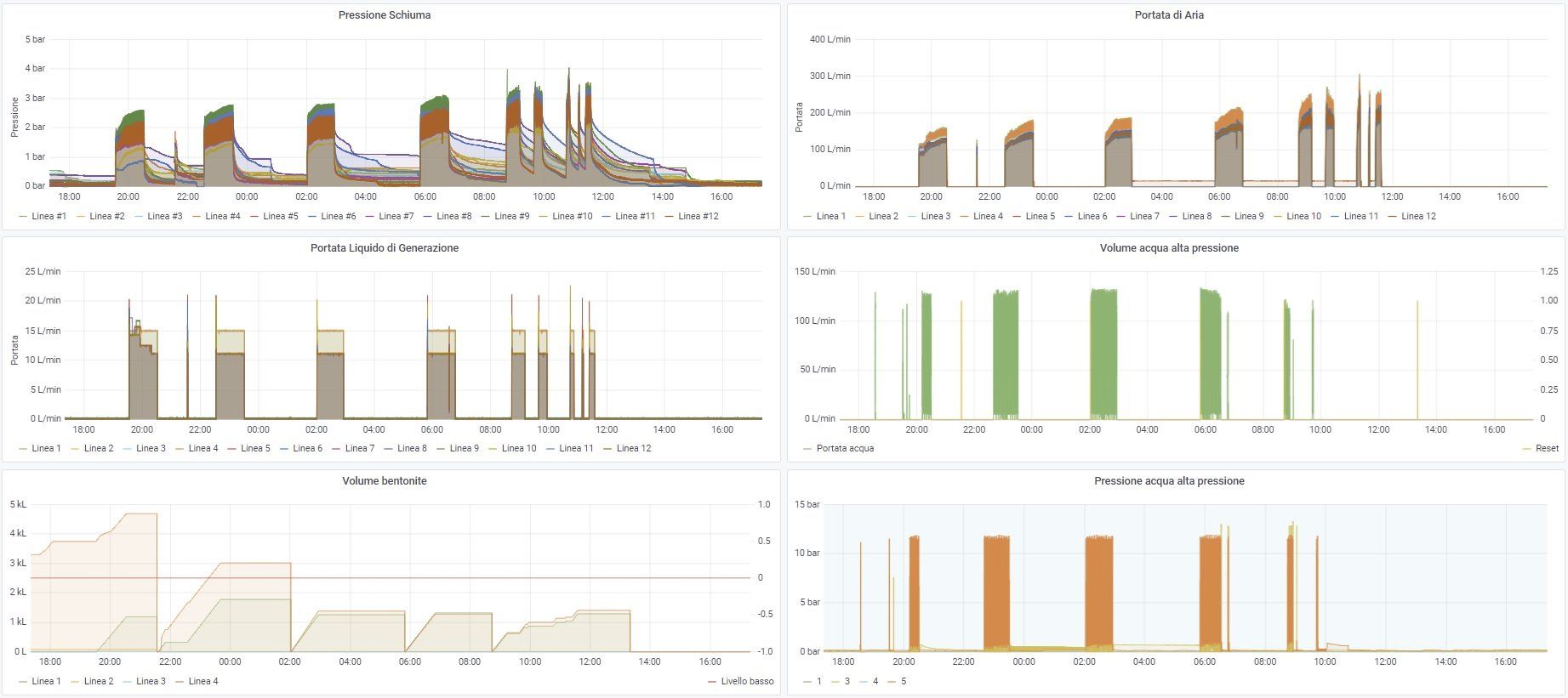

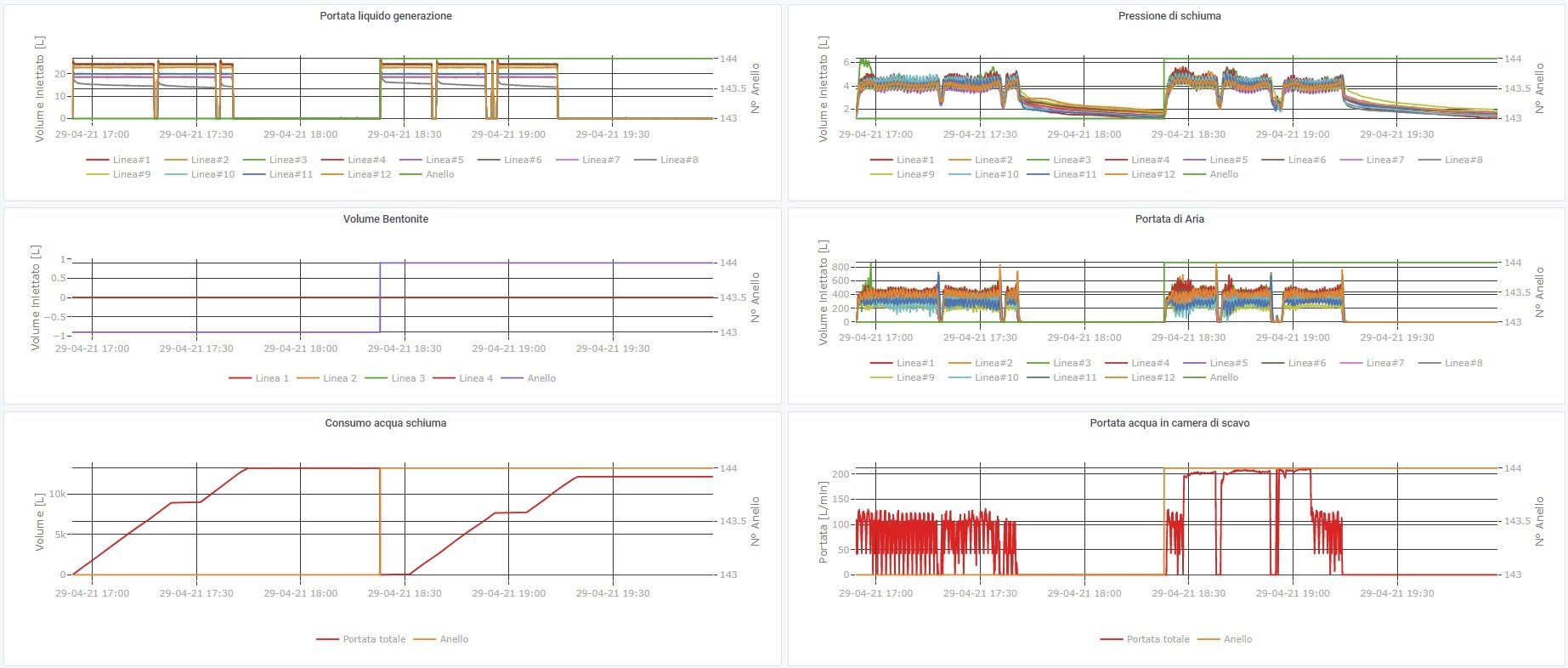

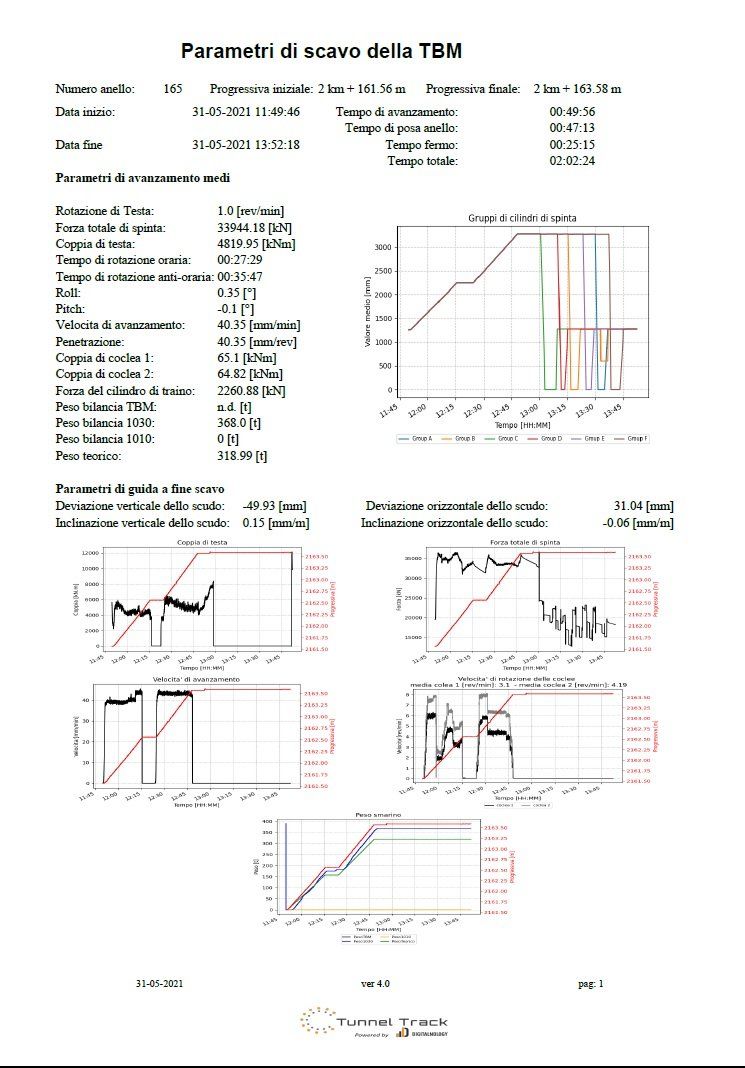

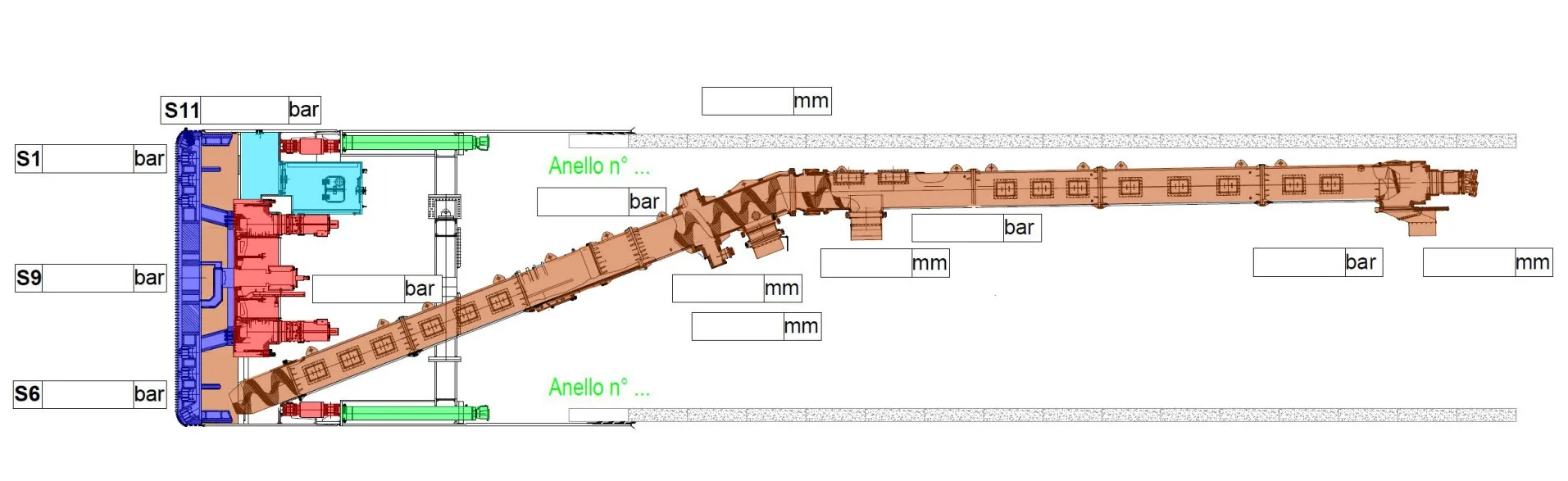

TBM OPERATING PARAMETERS

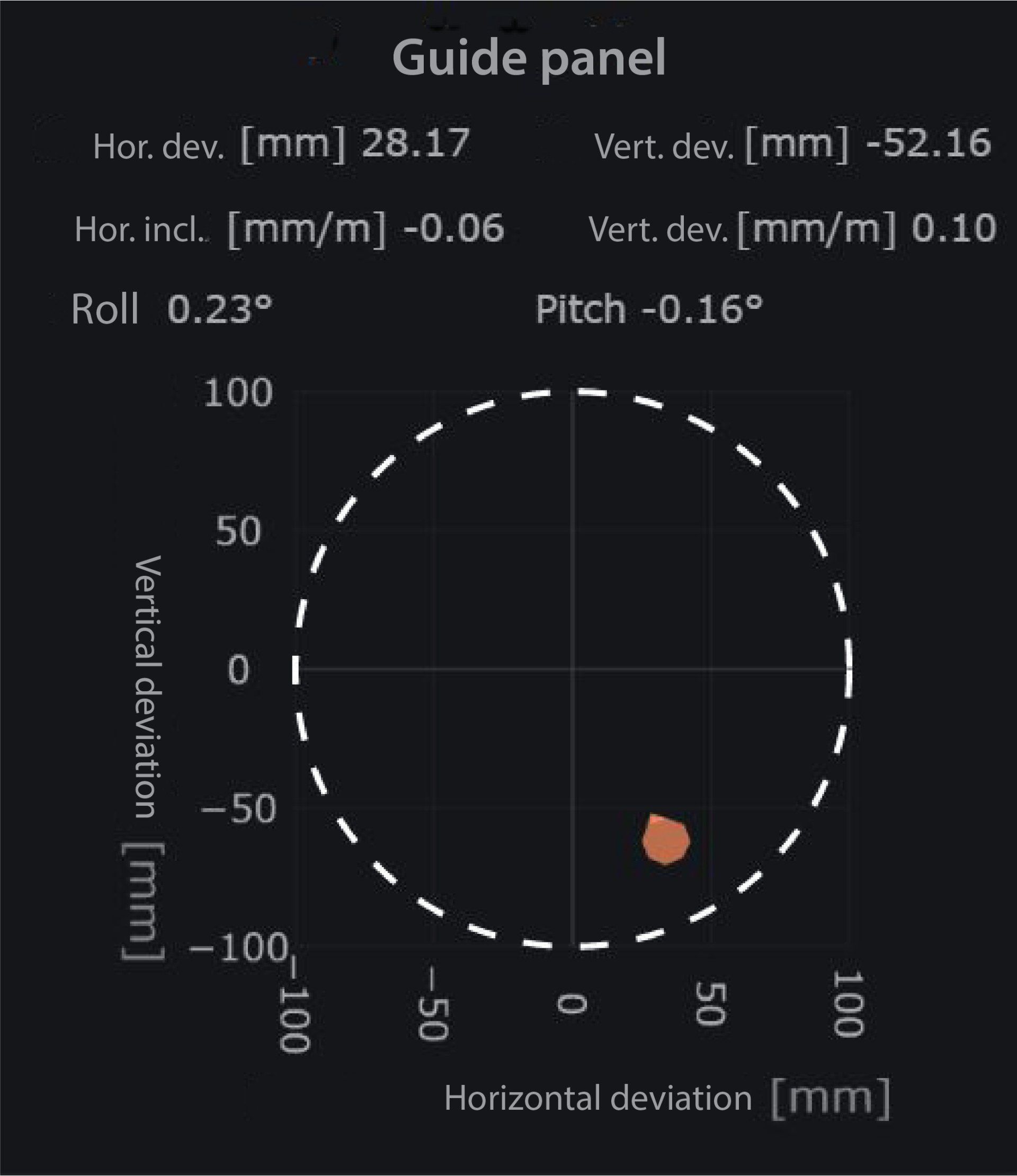

Surveying panel

Tunnel Track can also manage the data coming from any guidance system (PPS, VMT, TACS, CREG, CRCHI, ecc.). This component will help you visualize the guidance data of the TBM.

These parameters are:

- horizontal and vertical deviation of the shield;

- vertical and horizontal inclination of the shield;

- pitch and roll angle of the shield.

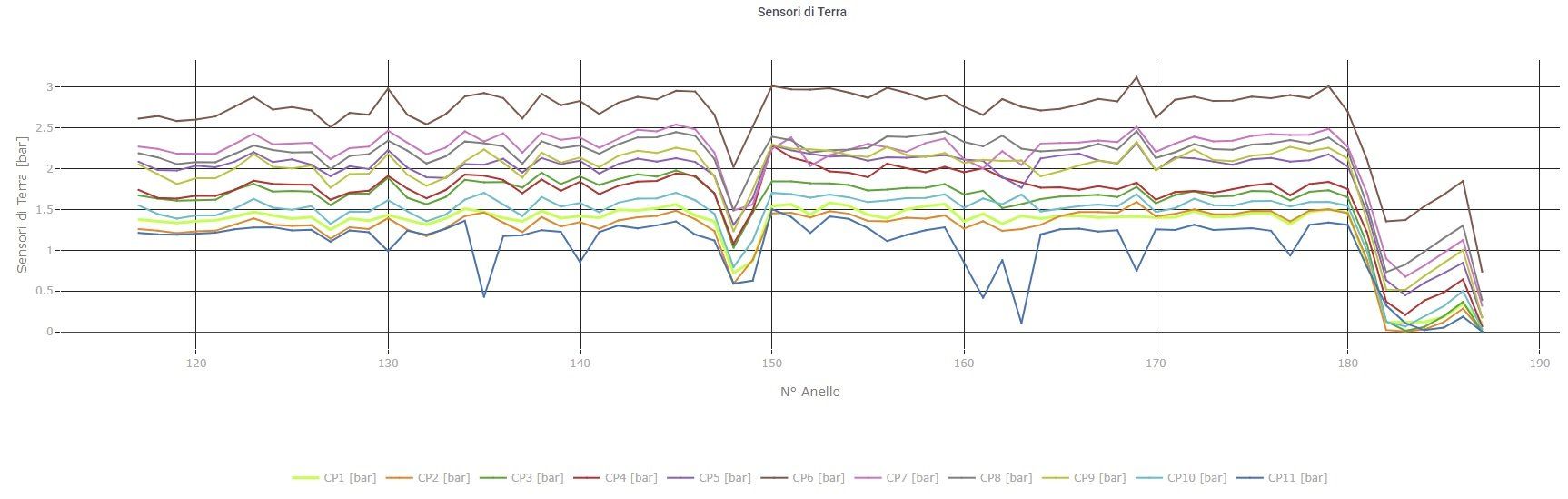

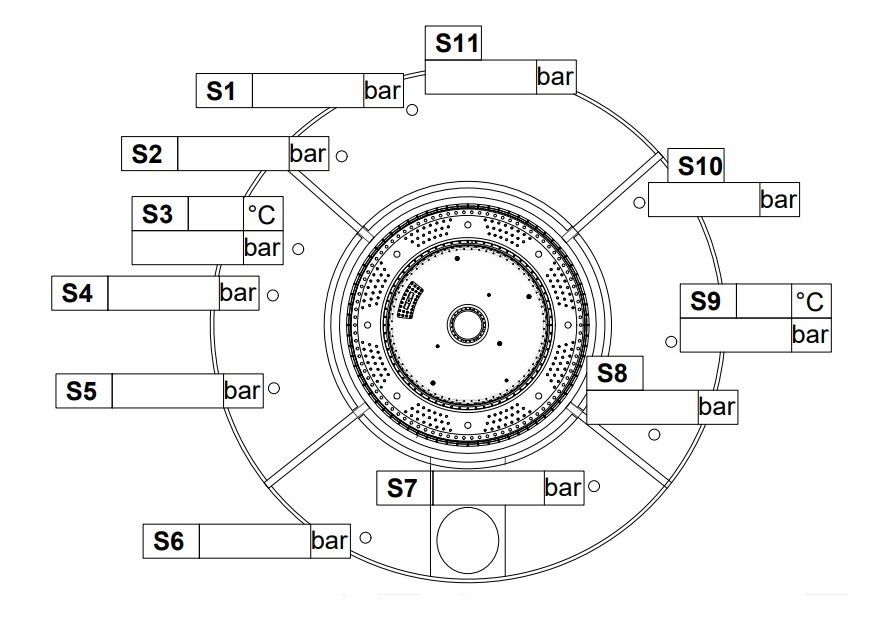

Pressure cells in the bulk chamber

This feature allows to visually check in real time the pressure values inside the bulk chamber, thanks to a personalized visualization.

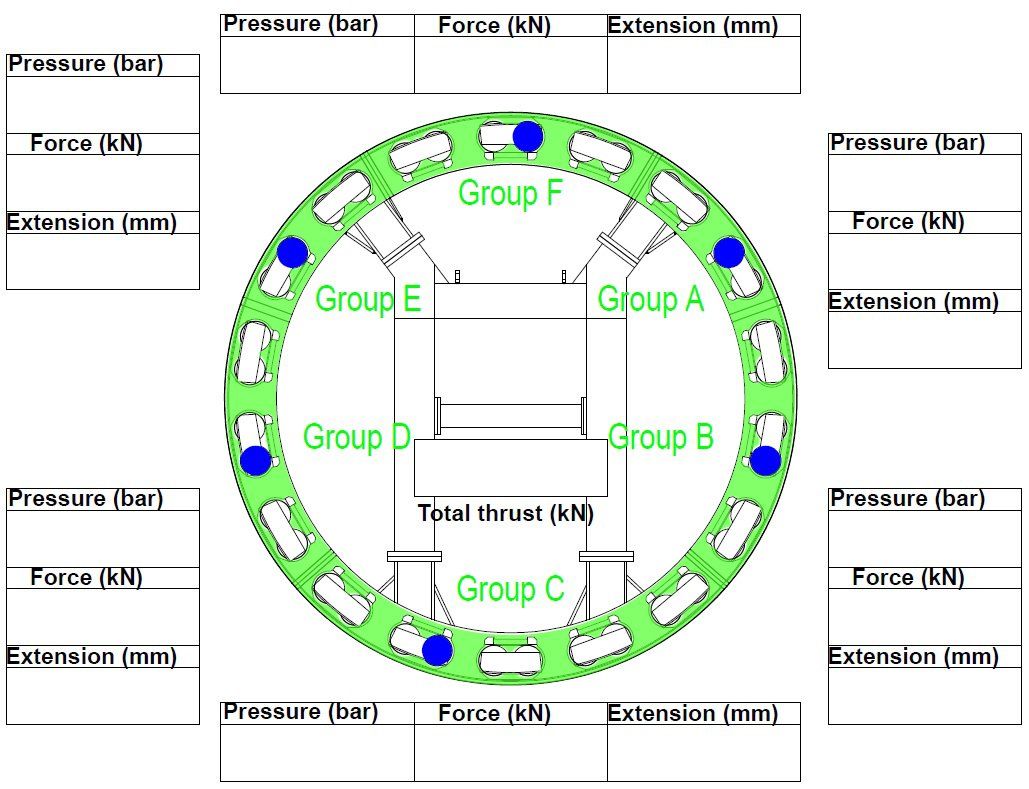

Thrust cylinders groups

This panel will let you understand the pressure exerted by the different thrust groups, their relative thrust, their extension and finally the total thrust exerted by the machine.

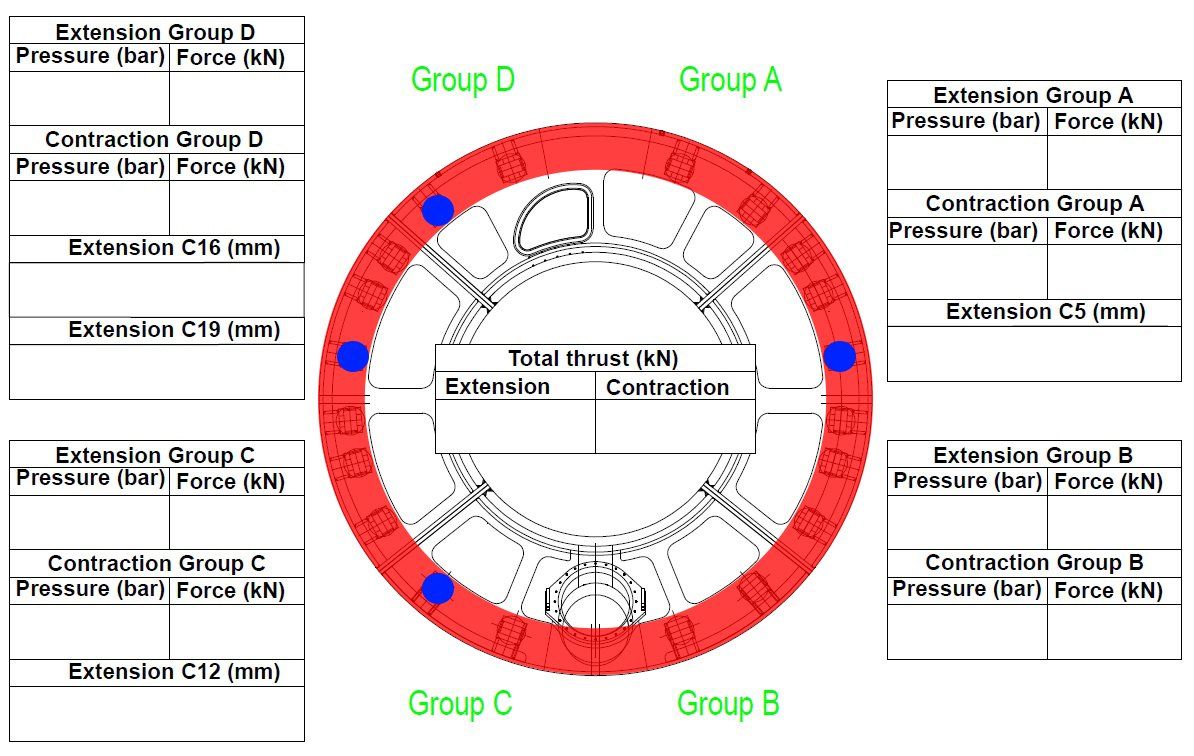

Articulation groups

When present, it will be possible to monitor the pressure values and the extension values of each articulation group.

General parameters of the TBM

This panel will help you monitor the main parameters of the TBM, such as pressure values in the bulk chamber, along the screw conveyor.

TBM’s position

This feature will help you understand the position of the TBM along the theoretical alignment of the tunnel.

BIG DATA ANALISIS

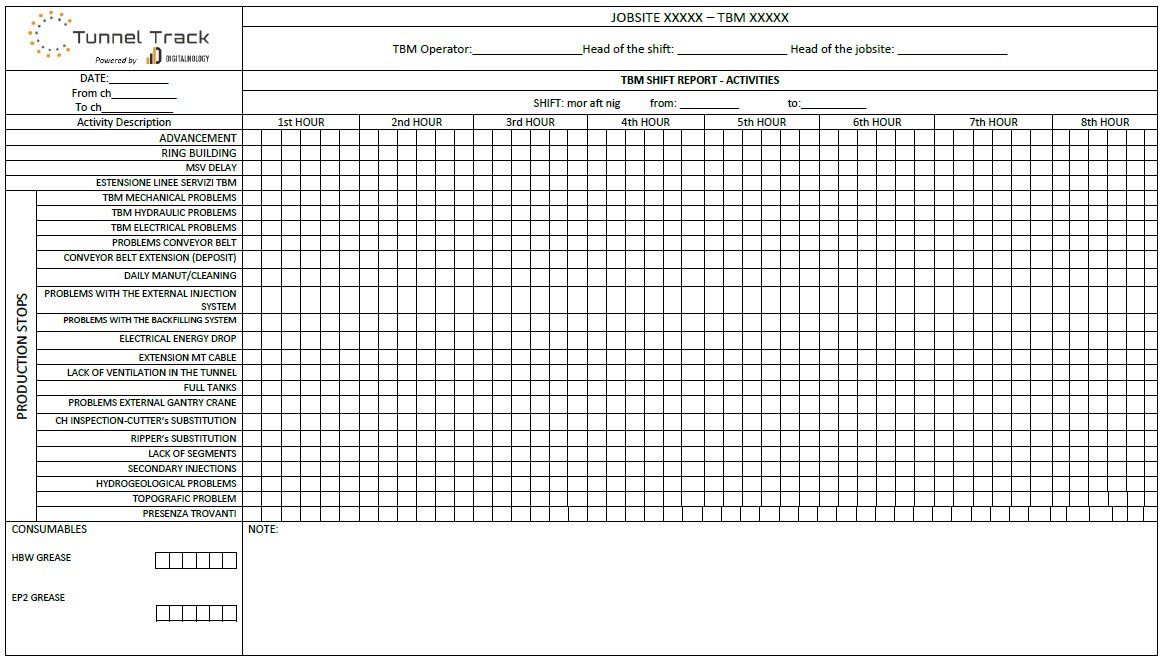

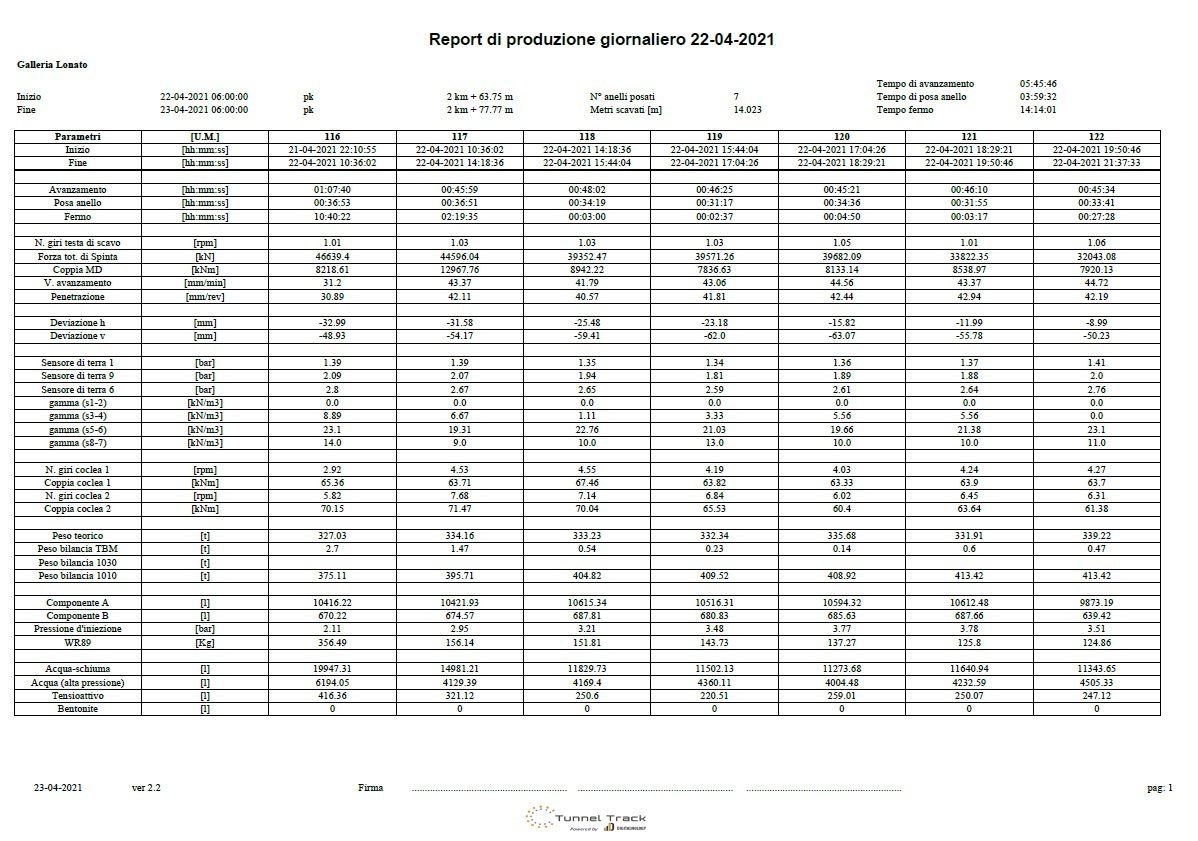

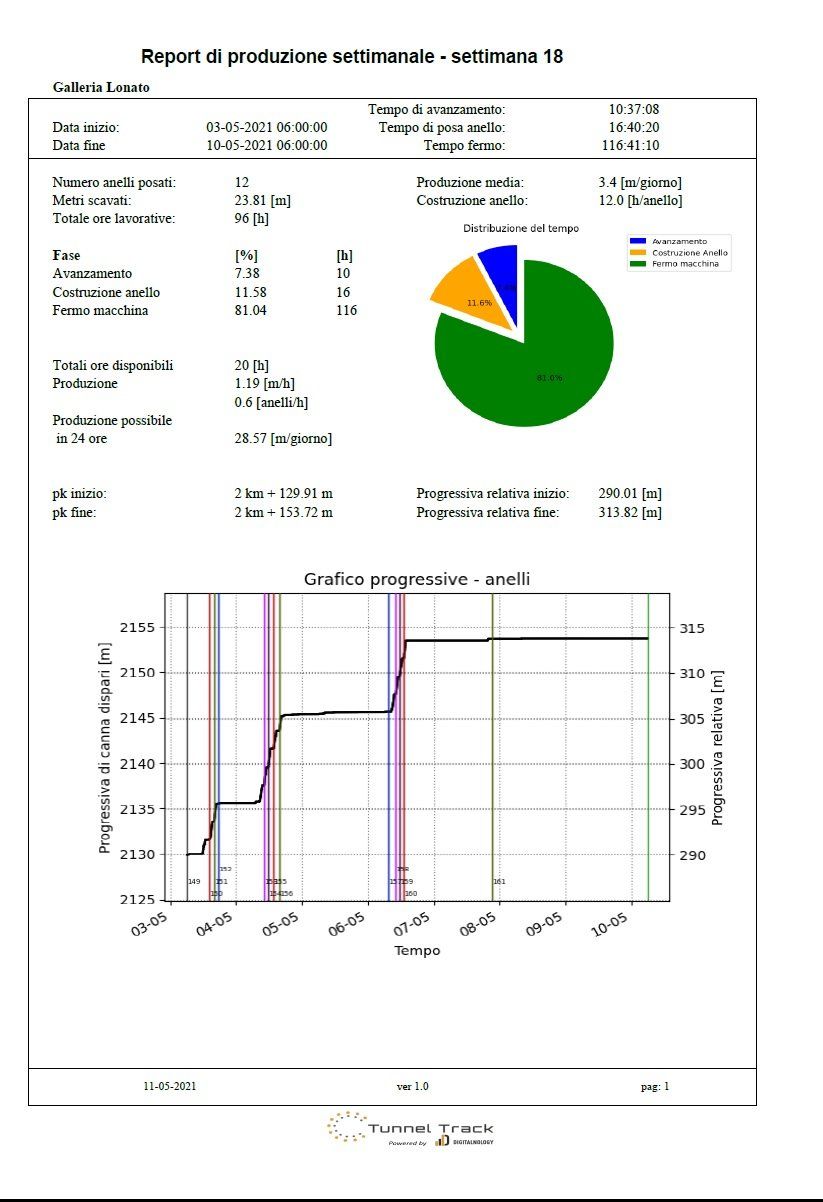

REPORTING

Thanks to our knowledge in the tunnelling sector, we can make any type of report you will need.

Our portfolio ranges from ring reports, daily and weekly reports to shift reports. All the reports are structured in agreement with the client, compiled automatically and then can be distributed to different teams, according to your needs.

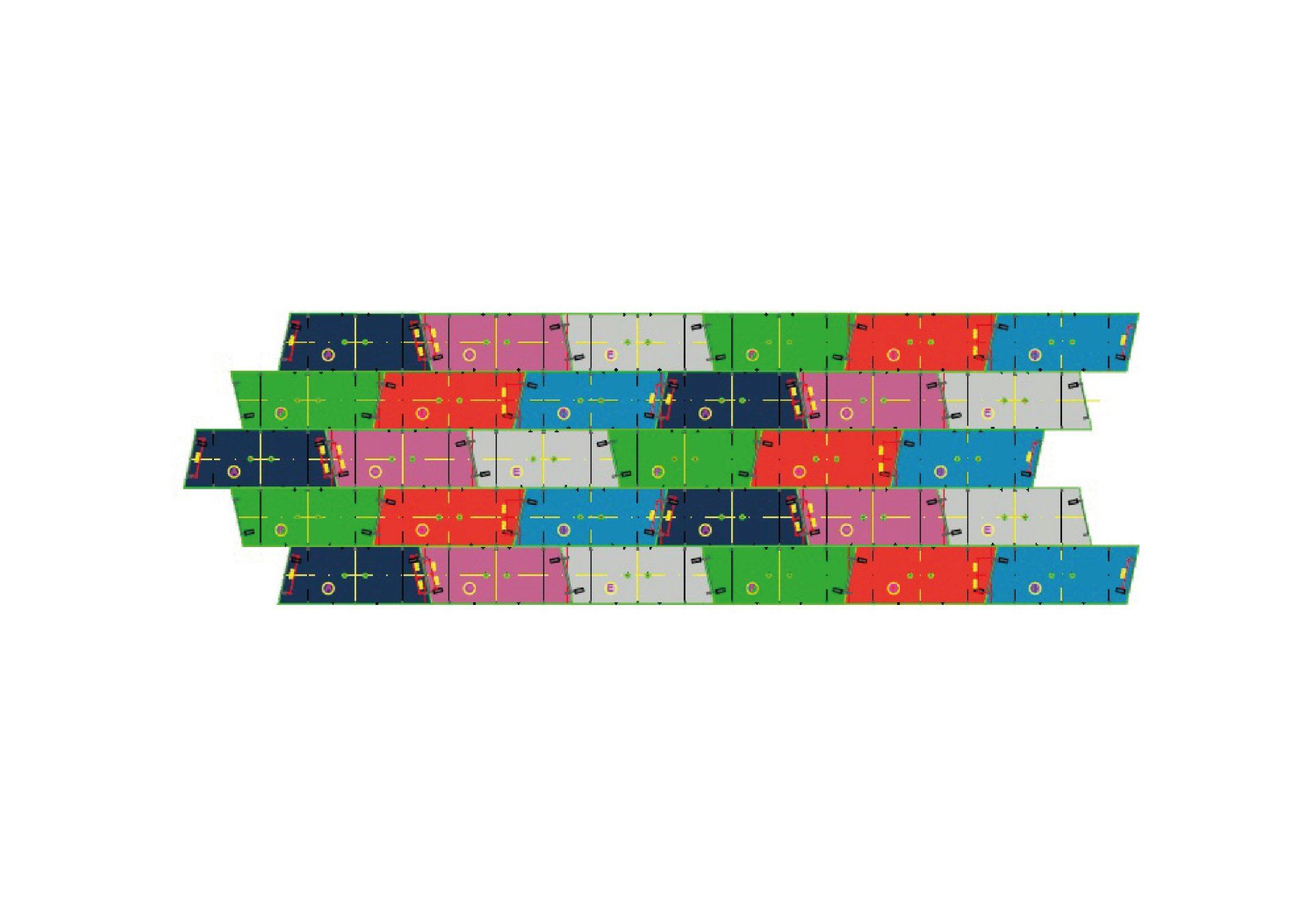

DEFECTS MANAGEMENT ON TBM SITE

- Information management of segments in real time

- Traceability of the end phase of the tunnelling process: from the storage in TBM to segments installation.

- Map for real-time tracking of segments position and real-time dashboard relating to segments quality.

- Data-Integration with the traceability system of the prefabrication plant

- Documentation and management of non-conformities in storage and transport

- Management of different tunnel projects with a unique platform