Digital Twin

Digital Twin created by Digitalnology to bringing tunnelling industry to 4.0

STEPS OF CREATION

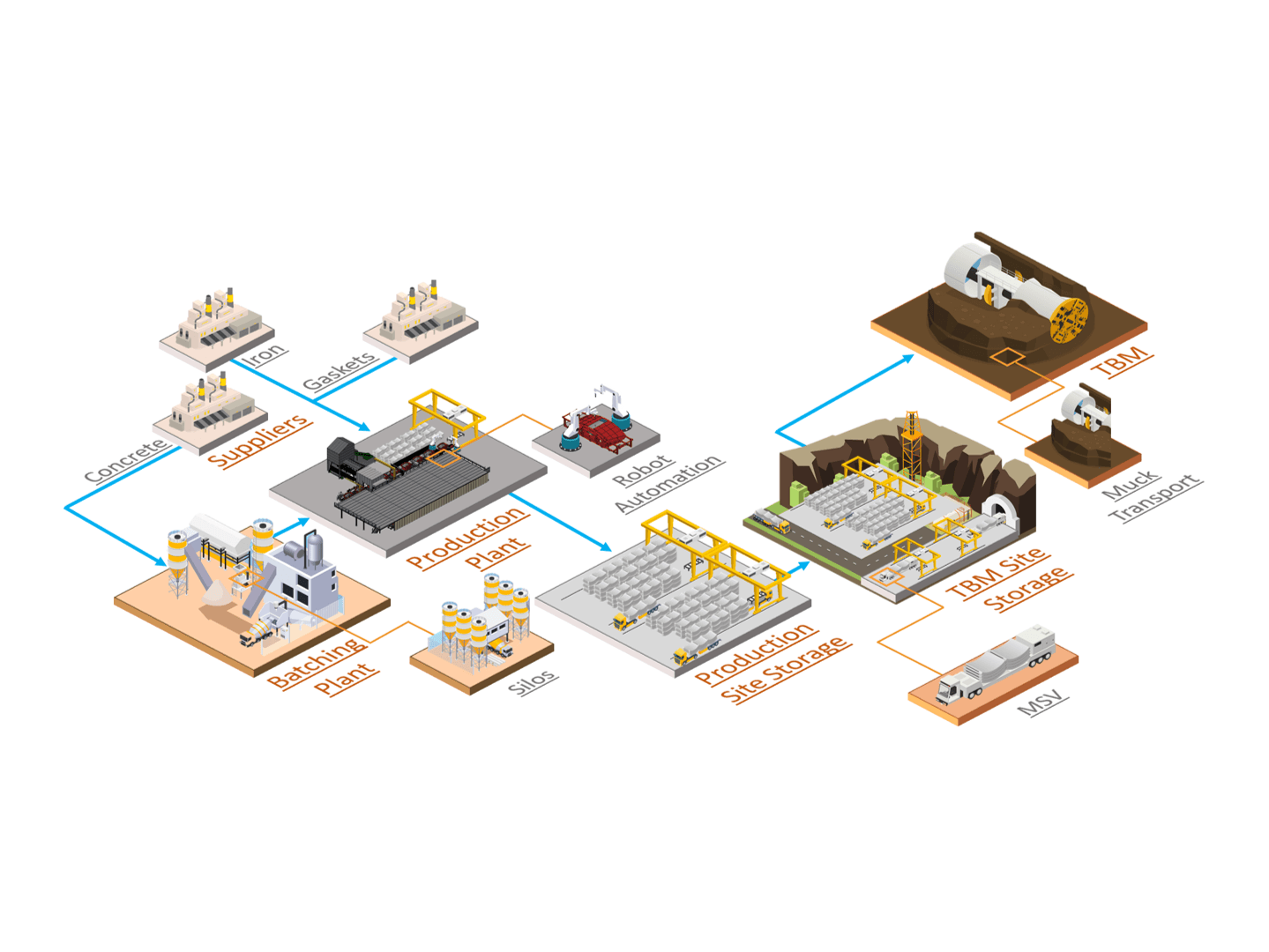

In the Tunnelling Construction, the creation of Digital Twin is divided in the following phases.

Within the photo features it is possible to see how Digital twin aides management through each step of the process:

from tunnel design, to long term maintenance, and asset management.

WHAT IS DIGITAL TWIN?

Digital Twin is a virtual replica of a physical entity, space, objects, people, and documents. In the world of construction and infrastructures,

Digital Twin is implemented for clients and their management teams.

The purpose of this digital solution is to give an overall view of the entire chain of the project in addition to the Physical Twin.

HOW DOES IT WORK?

A digital replica of a living or non-living physical entity.

The representation provides both the elements and the dynamics of how an Internet of things device operates and lives throughout its life cycle.

WHAT IS INVOLVED?

Using 3D and IoT Technologies is it possible to represent each aspect of the project at hand. Our clients can react and respond quickly to problems that may arise.

WHAT DO WE DELIVER?

Real Time Project Management Dashboard integrated with the precast management System KYP and the Tunnel Track System providing a 3D model of the Tunnel

Relevant information about the segment production and installation provided in open BIM format

A customized maintenance software with information relating to the main parts of the tunnel to be inspected and maintained and the estimated timing.